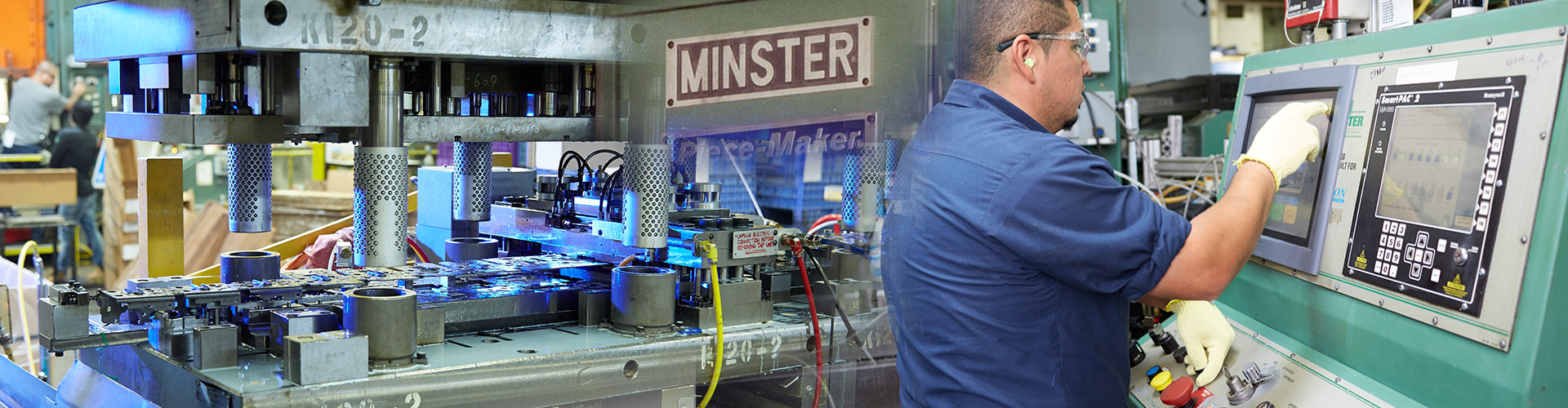

Stamping Equipment

Over 80 punch presses ranging from 30 to 660 tons and bed sizes up to 146” long, including high speed presses capable of running up to 1,500 SPM, are strategically positioned within our U.S. and Mexican manufacturing locations — resulting in a uniform offering across all plants. Total manufacturing space for all three locations exceeds 635,000 square feet. All three locations feature state of-the-art Wintriss sensor technology for the protection of tools.

We inspect part quality with each stroke of the press, and produce over 50 million parts per month for our customers. We employ advanced maintenance systems to ensure the availability and reliability of every piece of equipment. Continuing investment in new equipment and press room technology keeps IMS Buhrke-Olson up-to-date in adopting the latest metal stamping manufacturing processes.