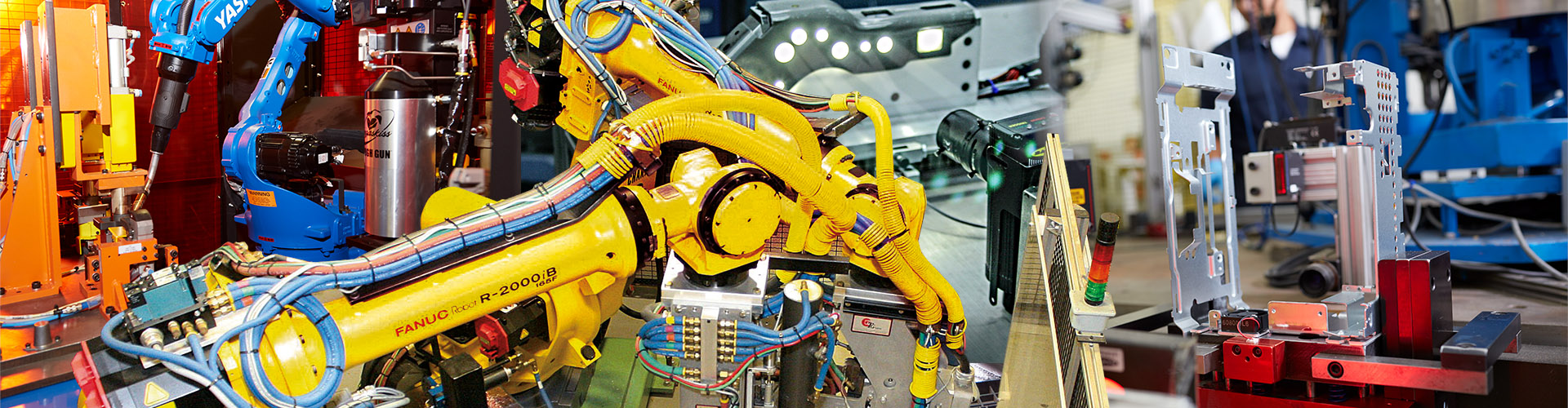

Automated Systems

IMS Buhrke-Olson design and builds both fully and semi-automated systems to perform resistance welding, MIG welding, TOX™ locking and component insertion. The design and build process for all of these systems is performed 100% in-house. We conduct a Design of Experiments (DOE) study on each application to assure reliability and repeatability during production.

Processes typically involve combining IMS Buhrke-Olson produced metal stampings as well as fasteners, adhesives, rubber, plastic, composites and other parts into a finished or semi-finished assembly. IMS Buhrke-Olson is fully staffed with bilingual electrical & mechanical engineers supporting all assembly line equipment using the latest technology to assure single-part flow and zero defect quality to our customers. The company is best known for the automated assembly of high volume components: items such as automotive airbag modules, entertainment system chassis, electronic engine control units and complicated bracket assemblies. All systems are designed and built to specifically meet customer needs and requirements.