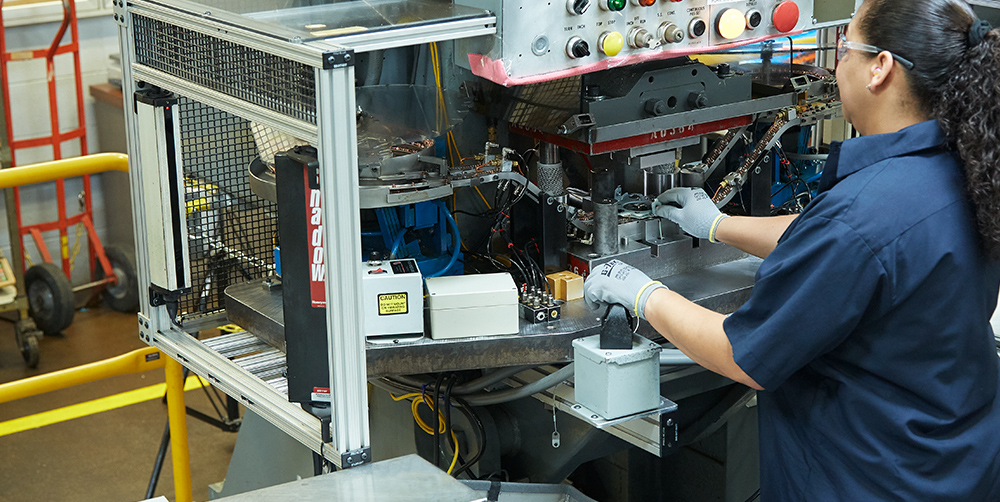

Complex In-Die Capabilities

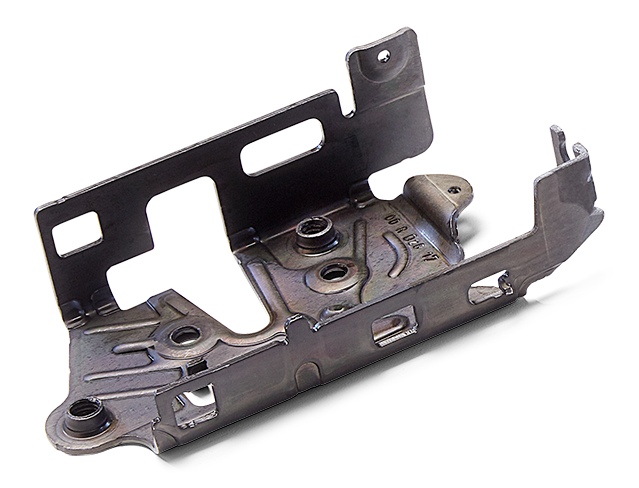

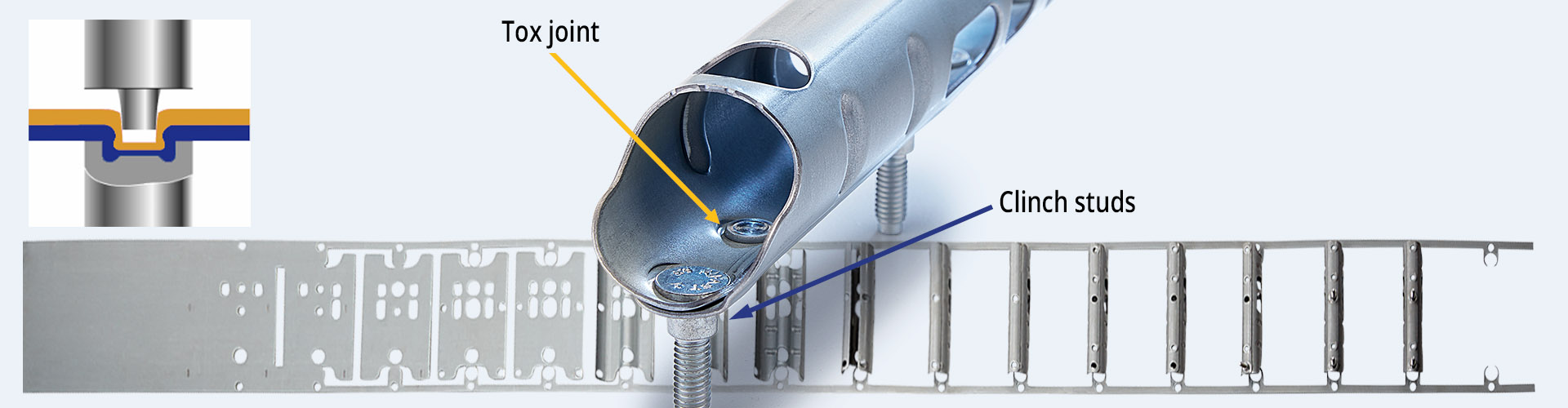

In order to drive out cost and improve quality, IMS Buhrke-Olson employs a variety of complex operations completed stroke by stroke under the press ram. Operations include inserting hardware, high speed servo tapping and complex joints in a mechanical assembly.

- Component insertion

- Reduced manufacturing cost

- Improved quality

- Servo tapping Systems

- Higher production speed

- Greater flexibility

- Reduced cost in multiple part applications

- Assembly